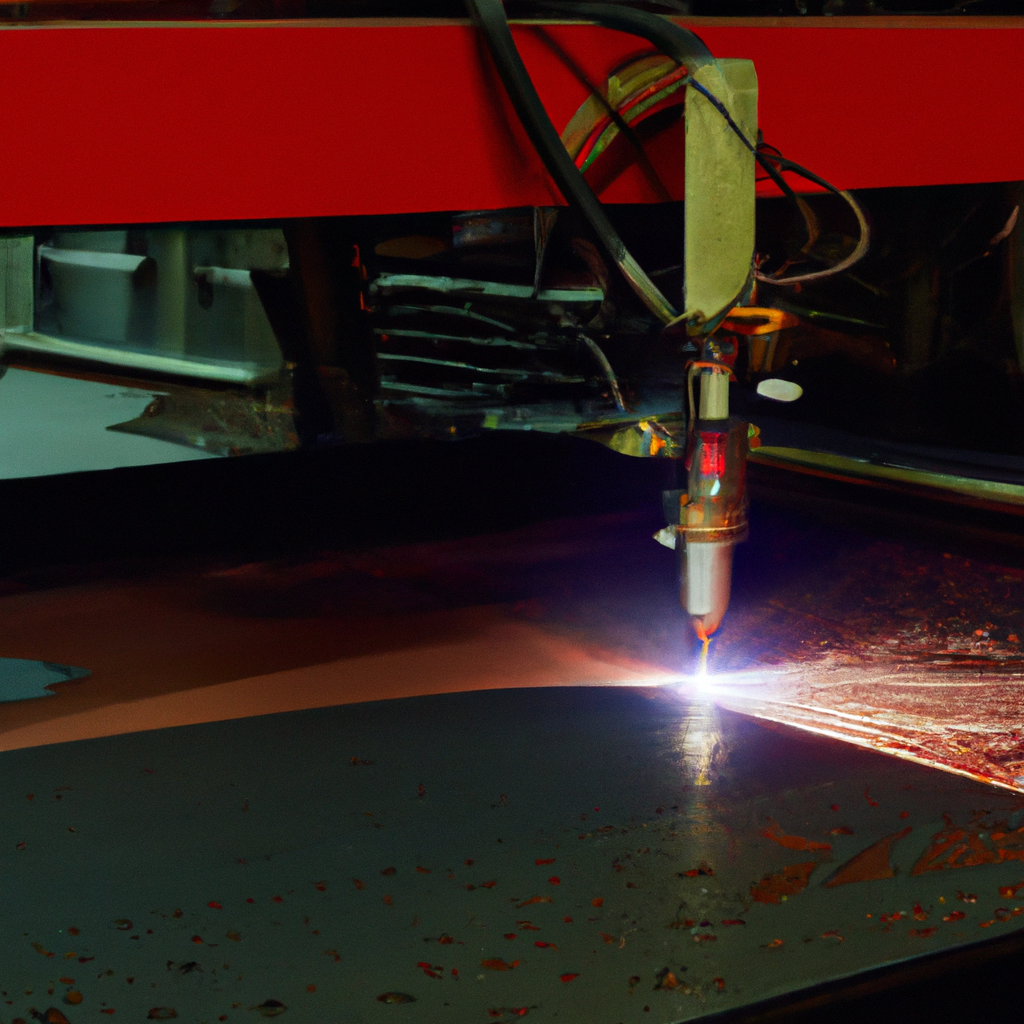

When it comes to modern manufacturing processes, CNC plasma cutters have become indispensable tool for businesses. These machines use high-temperature plasma to cut through various materials with precision and speed. Whether you are in the metal fabrication industry or involved in artistic creations, selecting the right CNC plasma cutter can significantly impact your productivity and the quality of your finished products.

In this article, we will guide you through the essential factors to consider when choosing a CNC plasma cutter that best suits your business needs.

1. Understanding CNC Plasma Cutting

Before diving into the selection process, it’s crucial to have a basic understanding of CNC plasma cutting. CNC stands for Computer Numerical Control, which means that the machine is controlled by computer programs that guide its movements. Plasma cutting involves using a high-velocity jet of ionized gas to melt and remove material from the workpiece. This process offers excellent cutting precision and versatility, making it suitable for a wide range of applications.

2. Assessing Your Business Requirements

To choose the right CNC plasma cutter, start by assessing your business requirements. Consider the type and thickness of the materials you typically work with, the desired cutting speed, and the level of intricacy in your designs. Understanding these factors will help you determine the power, size, and capabilities needed in a plasma cutter.

3. Power and Cutting Capacity

Power and cutting capacity are crucial factors to consider. The power of a CNC plasma cutter is measured in amps, and it directly affects its ability to cut through different materials. Thicker materials require higher amperage for efficient cutting. Evaluate your needs and choose a machine with sufficient power to handle your typical workload.

4. Cutting Speed and Accuracy

Efficiency is vital in any business, and a CNC plasma cutter’s cutting speed plays a significant role. Look for a machine that offers a balance between speed and accuracy, as both are important for maximizing productivity without compromising quality. Consider the machine’s maximum cutting speed and its ability to maintain precise cuts at varying speeds.

5. CNC Software and Interface

The CNC software and interface are the brains behind the plasma cutter. opt for a machine that comes with user-friendly software and an intuitive interface. This will make it easier for your operators to create, modify, and execute cutting programs. Compatibility with commonly used design software can also streamline your workflow.

6. Table Size and Work Area

The table size and work area of a CNC plasma cutter determines the maximum dimensions of the materials you can work with. Consider the size of the typical workpieces you handle and ensure that the machine’s table size accommodates them comfortably. A larger work area allows for more flexibility and enables you to undertake larger projects if necessary.

7. Torch Height Control

Torch height control is a critical feature that ensures consistent and precise cuts. It maintains the optimal distance between the torch and the workpiece, compensating for variations in material thickness or uneven surfaces. Look for a CNC plasma cutter with an advanced torch height control system to achieve clean and accurate cuts consistently.

8. Consumables and Maintenance

Like any machine, CNC plasma cutters require regular maintenance and the replacement of consumable parts. Before making a purchase, consider the availability and cost of consumables such as nozzles, electrodes, and shields. Additionally, inquire about the maintenance requirements of the machine and whether it requires specialized training for upkeep.

9. Safety Features

Safety should be a top priority in any workplace. Ensure that the CNC plasma cutter you choose incorporates essential safety features such as emergency stop buttons, protective barriers, and automatic shutdown mechanisms. Adequate ventilation and fume extraction systems are also crucial to maintain a safe working environment.

10. Price and Long-Term Investment

While price is a significant consideration, it’s important not to compromise on quality and features. A CNC plasma cutter is a long-term investment for your business, so consider the machine’s reliability, durability, and reputation of the manufacturer. Evaluate the machine’s overall value and choose the option that offers the best balance between quality and affordability.

In conclusion, selecting the right CNC plasma cutter for your business needs requires careful consideration of various factors. Assess your specific requirements, such as the materials you work with, cutting speed, and accuracy expectations. Consider the power and cutting capacity, software and interface, table size, torch height control, consumables, safety features, and long-term investment value. By making an informed decision based on these considerations, you can equip your business with a CNC plasma cutter that enhances productivity, delivers quality results, and contributes to your overall success